— Origially posted by Clay & Milk —

SAFI-Tech, an Iowa-based startup that is creating no-heat and low-heat solder and metallic joining products, is partnering with Indium Corporation.

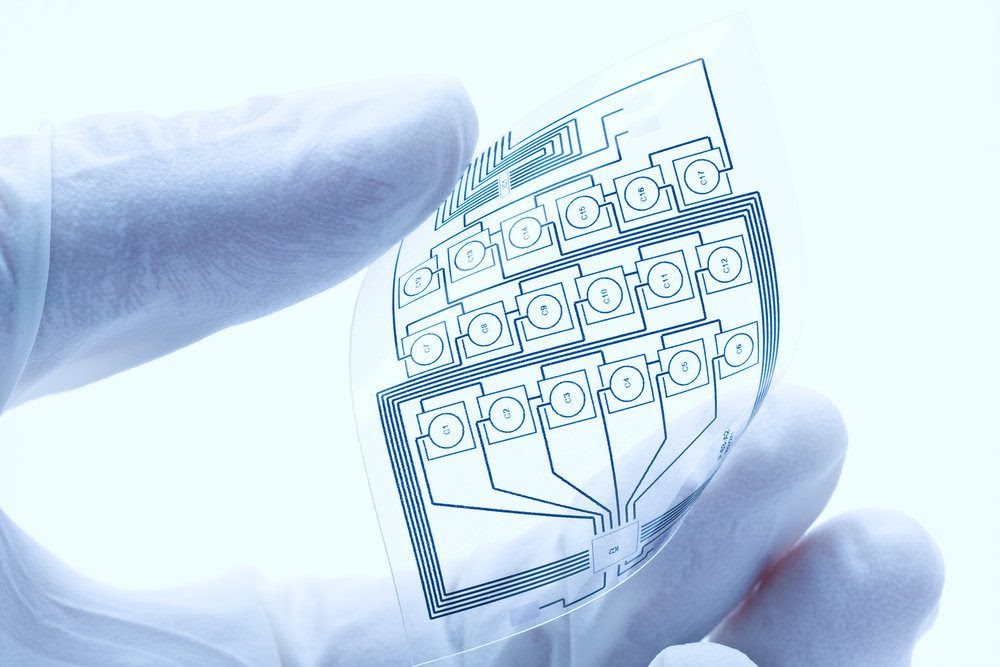

Safi-Tech has developed supercooled liquid metal particles that allow manufacturers to solder on flexible substrates without the use of heat. The liquid particles are about one-fiftieth the size of a human hair and are filled with liquid metal. When popped, the particles release the encapsulated liquid metal which quickly solidifies, creating a solder joint. This unique process allows soldering to take place at room temperature. Removing heat from electronics manufacturing enables smaller, thinner, and flexible designs, currently unachievable with standard materials and processes.

“Indium Corporation is a world leader and innovator in electronics solder products. Our partnership with Indium will allow customers to explore the unique opportunities possible with our supercooled solder materials,” said Ian Tevis, SAFI-Tech President and Co-Founder in a news release.

In 2020, the company was awarded an SBIR grant totaling $200,000 from the Department of Energy (DOE) to conduct research using its supercooled liquid metal microcapsule technology to enhance tools critical for research in high-energy particle physics.

Indium Corporation and SAFI-Tech said they will evaluate market applications for supercooled solder materials and explore the development of new products.

“We’re always looking for innovative materials solutions that can give our customers ways to overcome current limitations of solder products,” said Indium Corporation President and COO Ross Berntson. “SAFI-Tech’s supercooling platform is a unique approach that has the potential to be a solution across a variety of applications.”